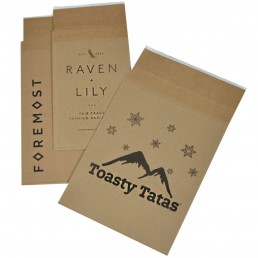

Product Lines

Customers Say

Reliable - Great - Valued - High PerformanceAlan Kossoff, US Box Corporation

We've been very pleased over the years. Bob Gant, Cox Paper & Printing

You are all wonderful to work with, and WCI is a top-notch company. It is always a pleasure working with you. WCI Customer

Your company is a pleasure to work with, many thanks to all. Please convey this message to all! WCI Customer

Honestly, if I were there I would hug you. Thank you so very much and if you will please, thank everyone (at WCI) for us. Seriously, with sincere thanks for all you do! WCI Customer

Thanks for responding to my request so quickly. Your response is just typical of the customer service work of WCI that I have had for the last 23 years. It has been great! WCI Customer

Our new bags arrived today and they look beautiful!! WCI Customer

Excellent service and quality. Broad color range of stock bags. WCI Customer

Your people are great; quick to respond, friendly and they know their information. WCI Customer

Exceptional quality, customer service, pricing, attention to detail. WCI Customer

Great customer service, great sales staff and great quality of product. WCI Customer

WCI has great intentions and integrity. They are great people and their dedication shows. WCI Customer

You are wonderful people to work with- I love it! I wish all my vendors were this amazing! Melanie Campbell, ARC Paper

Very easy to deal with. I'm always satisfied. Vivian Suffocal, TBL Packaging